Designing is a great profession, the crystallization of wisdom. It transforms what we know into product planning (or the product itself), making it us

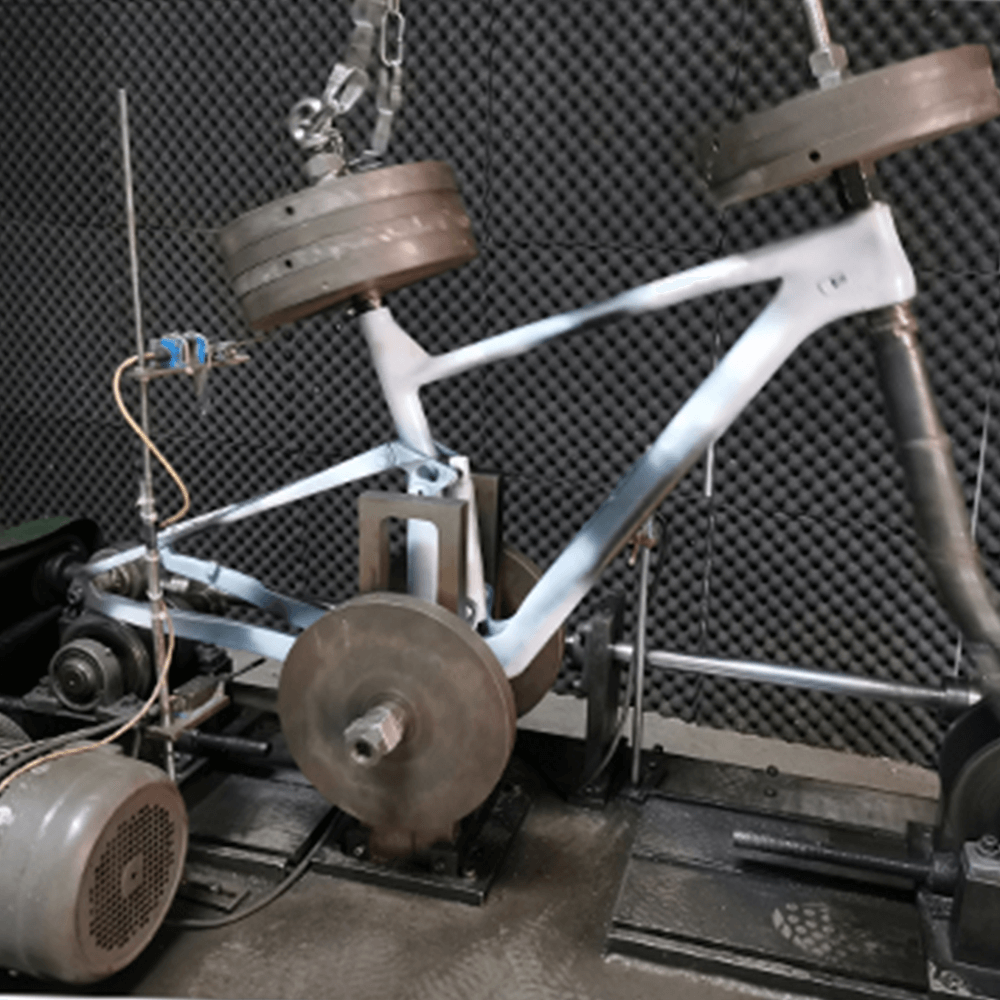

Lightcarbon Road and Mountain Bike Frame Test All LIGHTCARBON products will be tested strictly in accordance with EN or ISO4210, and will also be

LIGHTCARBON Bicycle Frame Production LIGHTCARBON manufactures and develops high end carbon fiber bicycle frames and accessories since 2016, has rich e

LightCarbon Rims Production Technology We use Toray T700 and T800 carbon fiber and cut The carbon fiber cloth into strips to prepare the preform of th

Carbon Bicycle Frame Quality Control 1. Check whether there is air leakage when the carbon frame is formed. Put the frame immersed in water, fill the

LightCarbon Decal And Painting Sample Pictures LightCarbon provides customized logo (decal) and color painting service for our carbon bike frames

Carbon Fiber Products Solution Carbon fiber square tubes Carbon fiber handiwork and other accessory covers carbon fiber automobile exhaust pipe and li

We will reply you within 24h after received your inquiry

We will reply you within 24h after received your inquiry

Who is LightCarbon? Xiamen LightCarbon Composite Technology Co., Ltd. is the leading manufacturer of carbon bike components in China. Our main products are: carbon frames and carbon wheels. 2012 – We set up a carbon frame factory in Huizhou City, Guangdong Province. Since then we started developing and manufacturing of carbon frames and carbon forks. 2015 – We cooperated with a carbon rim factory in Xiamen City, Fujian Province. In the same year, we set up international LightCarbon team, handling international sales and after-sales service. 2016 – We built another carbon frame factory in Xiamen City, which mainly focus on non-electric bike frames, including Road, Gravel, MTB and Fatbike carbon frames. 2017 – Our initial factory in Huizhou City converted main production to e-bike carbon frames, including e-MTB, e-Road, as well as other OEM and ODM e-bike carbon frames. Since then, we have two factories producing different categories of carbon frames. Starting from 2017, we exhibited in many global bike exhibitions, including Eurobike, Interbike, Cosmo Bike, etc. And have established business relationship with many well-known brands. 2019 – LightCarbon invested in a carbon rim factory (Xiamen ProX Carbon Technology Co., Ltd) which is located in Xiamen City. ProX team has more than 10 years’ experience in carbon rim manufacturing, and more than 4 years' experience in wheel building. With ProX team making carbon rims and wheelset for us, LightCarbon is able to more focus on carbon frame developing and manufacturing. If your main products are carbon rims and carbon wheels, please visit ProX Carbon website to see more detailed information and inquire our ProX team directly. What can we do for customers ▪ Customize logo, customize painting, as well as customize packaging (free artwork design). ▪ Develop your own mould carbon frames, rims, or other carbon components (ODM and OEM). ▪ Provide sales advice (based on the market information we get, sales record and customers' feedback, etc). ▪ In-time delivery (with the help of our order and production management system). ▪ 7x24 hours fast service support (both Pre-sale service and After-sale service). Why trust us? We have more than 20 engineers in our R&D Dept. Some of them have over 15 years experience in carbon frame bicycle industry, plus worked in OE factories for brands of Specialized, Cannondale, Pinarello etc... With the support of experienced R&D Dept., we are always in the leading for new products developing. All of our carbon frames and rims are made of high modulus carbon fiber (Toray T700, T800 and T1000), and they are tested under new ISO4210 standard. In addition, we raise the test standard up to 20% to do stricter testing. We never start mass production until our new products pass all the tests successfully. For the past few years, we started to use new 3D latex mandrel technology. Compared to traditional EPS or airbag technology, 3D latex mandrel technology helps to make carbon bike frames with smooth inner wall. In this way, the thickness of the same tube is quite even, no wrinkle inside, no weak point, so the quality of our carbon frame is very stable. Warranty: 2 years quality warranty is offered for all our carbon frames and forks, carbon rims and wheels. Click here to see details of LightCarbon Warranty Policy. At present, there are about 180 workers in our carbon rim factory, and about 150 workers in our carbon frame factory. Our current production capacity is: carbon frame ---> 2000 sets/month carbon fork ---> 3500 pcs/month carbon rim ---> 5000 pcs/month carbon wheel ---> 1200 pairs/month

read morecopyright © 2024 Lightcarbon Composite Technology Co.,Ltd.all rights reserved.

the professional team to service !

+86-592-6380131

+86-592-6380131 info@lightcarbon.com

info@lightcarbon.com Wendy | LightCarbon

Wendy | LightCarbon +86 18405052114

+86 18405052114