Product Test

categories

new products

LightCarbon Super Light Disc Brake Road Carbon Bike Frameset With Stem - Super Light weight! (870g/52cm) - Toray carbon fiber T700+T800+T1000 - Threaded T47 bottom bracket - Internal cable routing with specific stem - Max tire clearance 700C*32C - Flat mount disc brake, 140mm or 160mm - Front 12*100mm/Rear 12*142mm thru-axle - 2 years quality warranty more

LightCarbon Super Light Disc Brake Road Carbon Frameset With Integrated Handlebar - Super Light weight! (870g/52cm) - Toray carbon fiber T700+T800+T1000 - Threaded T47 bottom bracket - Max tire clearance 700C*32C - Flat mount disc brake, 140mm or 160mm - Full hidden cable routing - Front 12*100mm/Rear 12*142mm thru-axle - 2 years quality warranty more

LightCarbon Gravel Frameset With Micro Suspension System And Stem - With Micro Suspension system - With specific stem for hidden cable routing - 31.6mm seat post (dropper post compatible) - UDH rear derailleur hanger - Max tire clearance 700C*47C or 650B*1.95'' - Flat mount disc 140mm or 160mm - Front 12*100mm/Rear 12*142mm thru-axle more

LightCarbon Butterfly Weave C67DB Disc Brake Road Full Carbon Spoke Wheels - Buit with unique butterfly weave carbon rims - 28mm outer width (21mm inner width) - C67DB ceramic bearings hub, Rachet 36T structure - LC CS1 full carbon spokes, super light and stiff - UD/3K/12K/Marble matte/Marble glossy/ UD paintless - Shimano 11/12s or Sram 12s XDR cassette body - 2 years' quality warranty more

Butterfly Weave Road Disc Carbon Clincher Rims 28mm Width - Unique butterfly weave carbon rims - 33/38/45/55mm depths optional - 28mm outer width, 21mm inner width - Matte and glossy finish optional - Clincher (tubeless ready) - Designed for disc brake use - 2 years' quality warranty more

LightCarbon Gravel Frameset With Micro Suspension System And Integrated Handlebar - With Micro Suspension system - 31.6mm seat post (dropper post compatible) - UDH rear derailleur hanger - Max tire clearance 700C*47C or 650B*1.95'' - Flat mount disc 140mm or 160mm - Full hidden cable routing - Front 12*100mm/Rear 12*142mm thru-axle more

LightCarbon Ultra Light And Stiff Rim Brake Full Carbon Spoke Road Wheelset - R65 hubs 54T Ratchet system, ceramic bearings - Full carbon spokes, super light, stiff and aero - 25mm and 28mm width carbon rims optional - UD/3K/12K/Marble matte/Marble glossy/ UD paintless. - Tubeless ready, fit 700*25C-45C tire - 2 years quality warranty more

Carbon Rims/Wheels Test

LightCarbon Carbon Rims And Wheels Quality Control And Testing

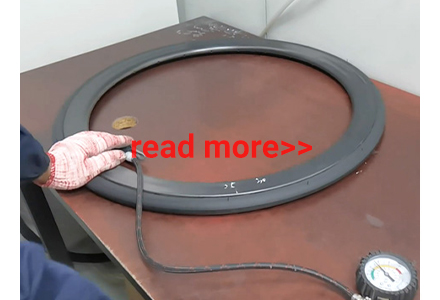

LightCarbon have strict quality control process and testing to make sure we deliver excellent quality carbon rims and wheels to customers. Every new product is tested for quality before it goes on sale to ensure durability and strength. After mass production, each batch of samples will be randomly tested to ensure the consistency of quality. Our rims need to go through a series of destructive and non-destructive tests. The main test consists of the following six test items: Spoke Tension Test, Inflation Test, Vertical Rigidity Test,Lateral Rigidity Test, Braking Test, Impact Test.

| Spoke Tension Test | Inflation Test | Vertical Rigidity Test |

|

|

|

|

Lateral Rigidity Test |

Braking Test |

Impact Test |

|

|

|

Quality control is from original top-level design to every production process.

Main process are Mold Check and Dimension Check:

Mold Check

1, Before each batch of production, check the mold condition to ensure that the mold and locking condition is good and clean.

2, After each batch of production, clean the mold again and put it in the special shelf marked with mold number.

3, Check whether the mold are classified as per Road and MTB, height and width of rims.

Dimension Check

1, After each process is completed, dimension check is carried out before proceeding to the next process.

2, Dimension check includes rim width, height, flatness, roundness, valve hole diameter, spoke hole diameter, hole distance, etc.

3, Check the edge finish to make sure there are no wrinkles or air bubbles.

next :

Carbon Frame Testcopyright © 2024 Lightcarbon Composite Technology Co.,Ltd.all rights reserved.

the professional team to service !

+86-592-6380131

+86-592-6380131 info@lightcarbon.com

info@lightcarbon.com Wendy | LightCarbon

Wendy | LightCarbon +86 18405052114

+86 18405052114