Production Process

categories

new products

LightCarbon Super Light Disc Brake Road Carbon Bike Frameset With Stem - Super Light weight! (870g/52cm) - Toray carbon fiber T700+T800+T1000 - Threaded T47 bottom bracket - Internal cable routing with specific stem - Max tire clearance 700C*32C - Flat mount disc brake, 140mm or 160mm - Front 12*100mm/Rear 12*142mm thru-axle - 2 years quality warranty more

LightCarbon Super Light Disc Brake Road Carbon Frameset With Integrated Handlebar - Super Light weight! (870g/52cm) - Toray carbon fiber T700+T800+T1000 - Threaded T47 bottom bracket - Max tire clearance 700C*32C - Flat mount disc brake, 140mm or 160mm - Full hidden cable routing - Front 12*100mm/Rear 12*142mm thru-axle - 2 years quality warranty more

LightCarbon Gravel Frameset With Micro Suspension System And Stem - With Micro Suspension system - With specific stem for hidden cable routing - 31.6mm seat post (dropper post compatible) - UDH rear derailleur hanger - Max tire clearance 700C*47C or 650B*1.95'' - Flat mount disc 140mm or 160mm - Front 12*100mm/Rear 12*142mm thru-axle more

LightCarbon Butterfly Weave C67DB Disc Brake Road Full Carbon Spoke Wheels - Buit with unique butterfly weave carbon rims - 28mm outer width (21mm inner width) - C67DB ceramic bearings hub, Rachet 36T structure - LC CS1 full carbon spokes, super light and stiff - Shimano 11/12s or Sram 12s XDR cassette body - 2 years' quality warranty more

Butterfly Weave Road Disc Carbon Clincher Rims 28mm Width - Unique butterfly weave carbon rims - 33/38/45/55mm depths optional - 28mm outer width, 21mm inner width - Matte and glossy finish optional - Clincher (tubeless ready) - Designed for disc brake use - 2 years' quality warranty more

LightCarbon Gravel Frameset With Micro Suspension System And Integrated Handlebar - With Micro Suspension system - 31.6mm seat post (dropper post compatible) - UDH rear derailleur hanger - Max tire clearance 700C*47C or 650B*1.95'' - Flat mount disc 140mm or 160mm - Full hidden cable routing - Front 12*100mm/Rear 12*142mm thru-axle more

LightCarbon Ultra Light And Stiff Rim Brake Full Carbon Spoke Road Wheelset - R65 hubs 54T Ratchet system, ceramic bearings - Full carbon spokes, super light, stiff and aero - 25mm and 28mm width carbon rims optional - Tubeless ready, fit 700*25C-45C tire - 2 years quality warranty more

Quality Control

Carbon Bicycle Frame Quality Control

1. Check whether there is air leakage when the carbon frame is formed. Put the frame immersed in water, fill the air into the frame by an air gun. If no bubble then determination frame is in good condition, then transfer to the next step. This step was the most strict QC inspection, leak products cannot be repaired and shipped, because the leak will affect the structural strength, only for scrap.

2. Check the flatness on the platform, fixed frame BB, with false hub fixed frame after claw, simulation wheel assembly on the frame. 3&4 images fix frame on the platform checked whether the left and right sides of the rear seat stay and chain stay are parallel. If OK, turn to the next process. Otherwise, return to repair.

5. Inspect the right side frame on the platform with precision height gauges, and adjust the height data to the center of the frame BB and return to zero.

6. Adjust the height gauge to the center of the frame to measure slowly along the die line of the down tube of the frame. The height gauge to the position of the down tube near head tube stops as shown in pic 7

Check whether the center of the height gauge is on the same place as the down tube of the frame with tolerance 1.5mm if within this range determine OK, otherwise, it needs to be repaired.

7. Use the same method as above step 6 to check the top tube. Above check items were for frame Alignment, If the front and rear wheels are not in the same center, the problem of wheel misalignment will occur.

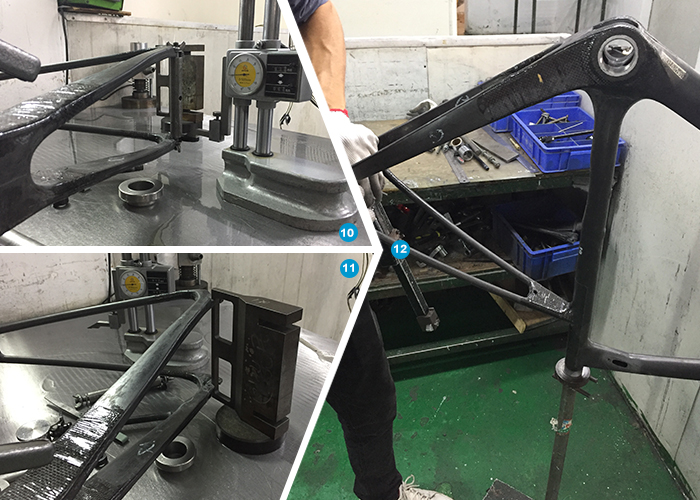

10. The height gauge is zeroed on the inner side of the right claw of the frame to confirm whether the center point of the rear stay width of the frame is on the same center line with the center line of the BB, the tolerance is 1.5mm.

11. Check whether the left and right hooks are on the same plane with the checking fixture of the Hook groove plane. There is no tolerance requirement for this checking, but it is guaranteed to be on the same plane, such as the left and right hooks are not on the same plane after the wheel build up, there will be left and right deviation and will influence the ride.

12. When the left and right in pic 11 needed to be on the same plane, the tire position check mode of Fig. pic 13 was added, fixing the tire position meter in the frame check slot, and measuring the data on the left and right side of the seat stay That is, the value of Ar Triangle of A-B is less than 1MM (Road), and A-B is less than 1.5 mm (MTB). Otherwise, it needs to be fixed.

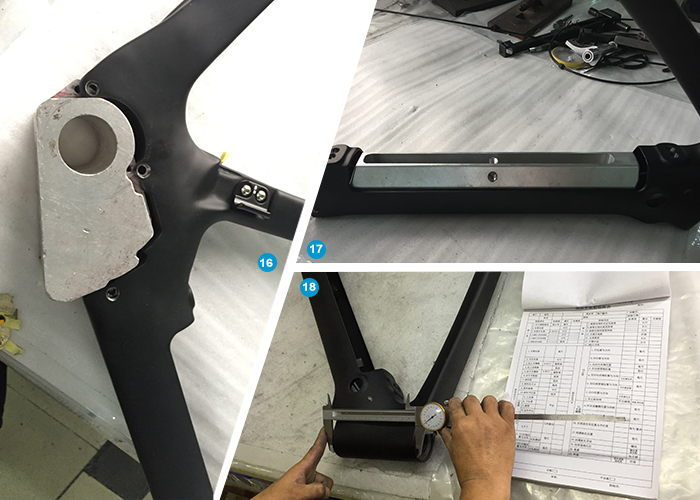

14. Check whether the head Tube size according to the FSA set standard production, this test way is GO / Ng.

15. Check that the disc brake dimensions are made to Shimano specifications. This test is GO / Ng.

16. Check the E-BIKE frame motor assembly part of the size setting and battery mount uses the mockup jigs.

21. According to the frame design of geometric dimensions and tolerance inspection assembly size, and according to the structure design set weight standard 100% inspection, such as pic 18, pic 19, pic 20, the final inspection report each rack has a final shipping report, as shown in figure 21, which records the dimensions and weight inspected data will keep for two years.

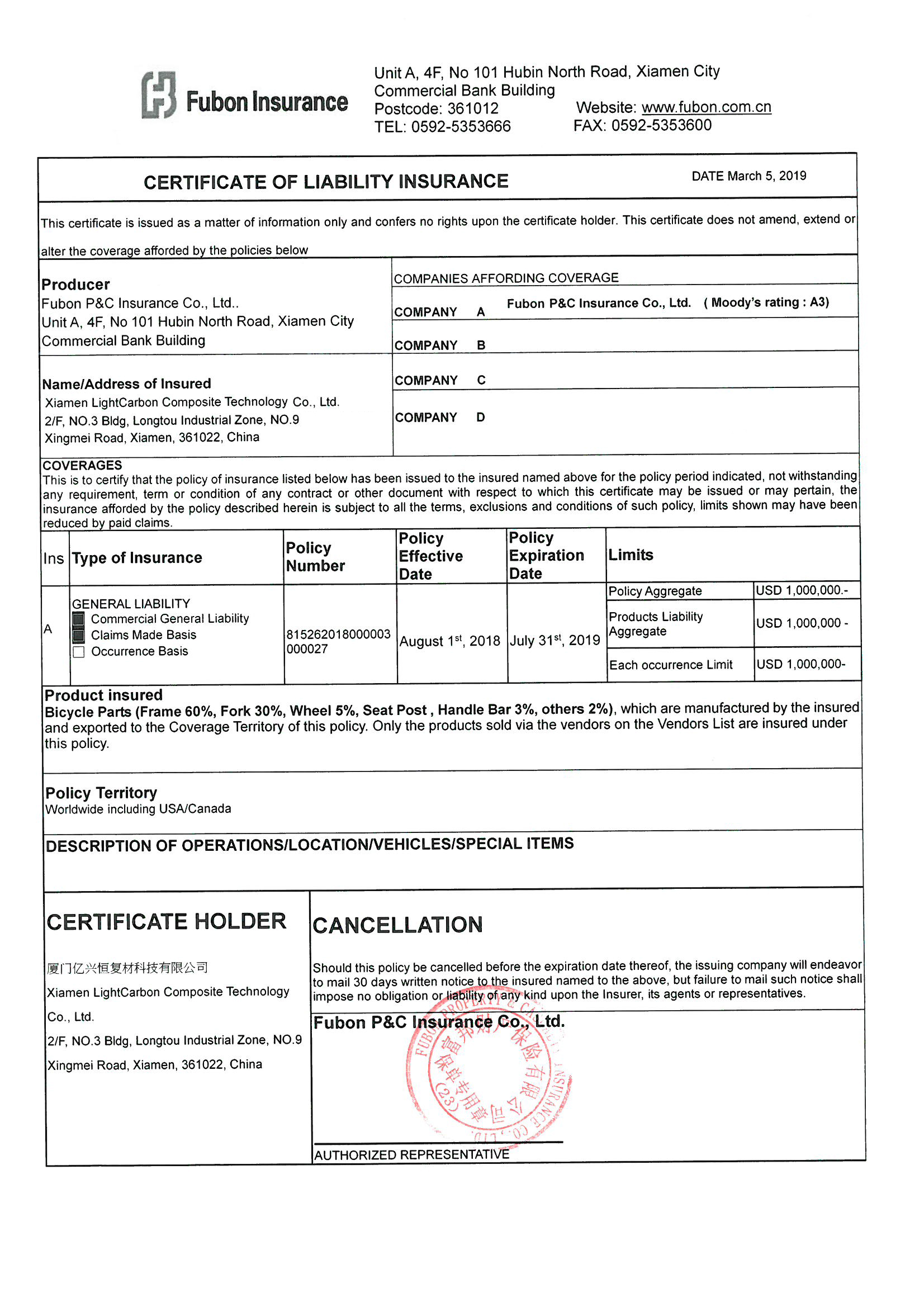

We also have insurance for our products.

previous :

Rims Productionnext :

Development & Designcopyright © 2024 Lightcarbon Composite Technology Co.,Ltd.all rights reserved.

the professional team to service !

+86-592-6380131

+86-592-6380131 info@lightcarbon.com

info@lightcarbon.com Wendy | LightCarbon

Wendy | LightCarbon +86 18405052114

+86 18405052114