Production Process

categories

new products

LightCarbon Super Light Disc Brake Road Carbon Bike Frameset With Stem - Super Light weight! (870g/52cm) - Toray carbon fiber T700+T800+T1000 - Threaded T47 bottom bracket - Internal cable routing with specific stem - Max tire clearance 700C*32C - Flat mount disc brake, 140mm or 160mm - Front 12*100mm/Rear 12*142mm thru-axle - 2 years quality warranty more

LightCarbon Super Light Disc Brake Road Carbon Frameset With Integrated Handlebar - Super Light weight! (870g/52cm) - Toray carbon fiber T700+T800+T1000 - Threaded T47 bottom bracket - Max tire clearance 700C*32C - Flat mount disc brake, 140mm or 160mm - Full hidden cable routing - Front 12*100mm/Rear 12*142mm thru-axle - 2 years quality warranty more

LightCarbon Gravel Frameset With Micro Suspension System And Stem - With Micro Suspension system - With specific stem for hidden cable routing - 31.6mm seat post (dropper post compatible) - UDH rear derailleur hanger - Max tire clearance 700C*47C or 650B*1.95'' - Flat mount disc 140mm or 160mm - Front 12*100mm/Rear 12*142mm thru-axle more

LightCarbon Butterfly Weave C67DB Disc Brake Road Full Carbon Spoke Wheels - Buit with unique butterfly weave carbon rims - 28mm outer width (21mm inner width) - C67DB ceramic bearings hub, Rachet 36T structure - LC CS1 full carbon spokes, super light and stiff - UD/3K/12K/Marble matte/Marble glossy/ UD paintless - Shimano 11/12s or Sram 12s XDR cassette body - 2 years' quality warranty more

Butterfly Weave Road Disc Carbon Clincher Rims 28mm Width - Unique butterfly weave carbon rims - 33/38/45/55mm depths optional - 28mm outer width, 21mm inner width - Matte and glossy finish optional - Clincher (tubeless ready) - Designed for disc brake use - 2 years' quality warranty more

LightCarbon Gravel Frameset With Micro Suspension System And Integrated Handlebar - With Micro Suspension system - 31.6mm seat post (dropper post compatible) - UDH rear derailleur hanger - Max tire clearance 700C*47C or 650B*1.95'' - Flat mount disc 140mm or 160mm - Full hidden cable routing - Front 12*100mm/Rear 12*142mm thru-axle more

LightCarbon Ultra Light And Stiff Rim Brake Full Carbon Spoke Road Wheelset - R65 hubs 54T Ratchet system, ceramic bearings - Full carbon spokes, super light, stiff and aero - 25mm and 28mm width carbon rims optional - UD/3K/12K/Marble matte/Marble glossy/ UD paintless. - Tubeless ready, fit 700*25C-45C tire - 2 years quality warranty more

Rims Production

LightCarbon Rims Production Technology

We use Toray T700 and T800 carbon fiber and cut The carbon fiber cloth into strips to prepare the preform of the Carbon rims

After the rims pre-molding then put into the high-temperature press molding table, wait for the specified time to complete the rims molding

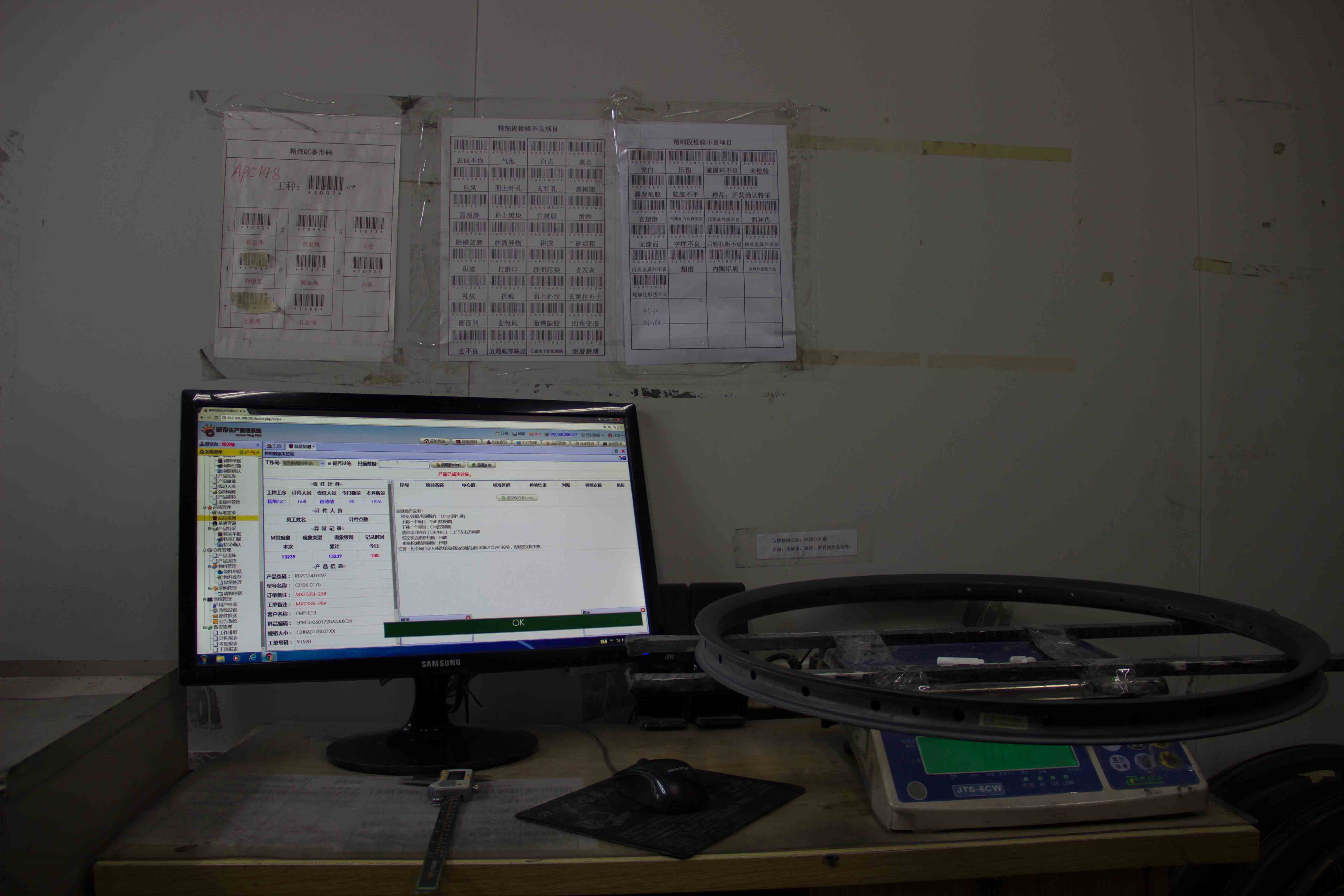

LightCarbon carbon bicycle rims production workshop

Scan the serial number label and apply on the carbon rims slot for tracking and record when rims are produced. This label also was proof for warranty and replacement

Use the auto machine check the carbon rims roundness and production system to tracking each rims weight was reach the standard

Finally, according to the customers order rims spec to arrange for packed and prepare for release the rims

previous :

Decal & Paintingnext :

Quality Controlcopyright © 2024 Lightcarbon Composite Technology Co.,Ltd.all rights reserved.

the professional team to service !

+86-592-6380131

+86-592-6380131 info@lightcarbon.com

info@lightcarbon.com Wendy | LightCarbon

Wendy | LightCarbon +86 18405052114

+86 18405052114